Subtotal $0.00

Welcome to Pan-Technik GmbH. We offer many years of expertise in the field of hydrocyclones and offer tailor-made solutions for your requirements.

Competence that creates trust

Competence that creates trust

Als ein führender Anbieter von Hydrozyklonen und Wasseraufbereitungssystemen setzen wir auf Qualität, Innovation und Zuverlässigkeit. Unser Ziel ist es, maßgeschneiderte Lösungen zu entwickeln und langfristige Partnerschaften aufzubauen, um Ihren Erfolg zu sichern.

Since 1995, Pan Technik has been delivering first-class hydrocyclone and filter systems through experience and innovation.

Our hydrocyclones offer outstanding performance and efficiency in separating particles from liquids.

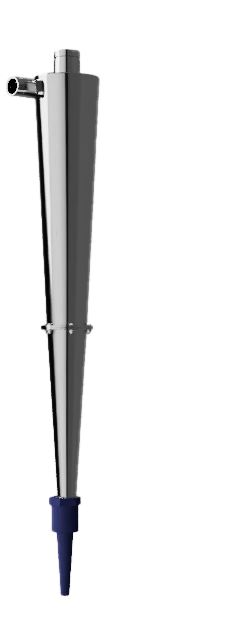

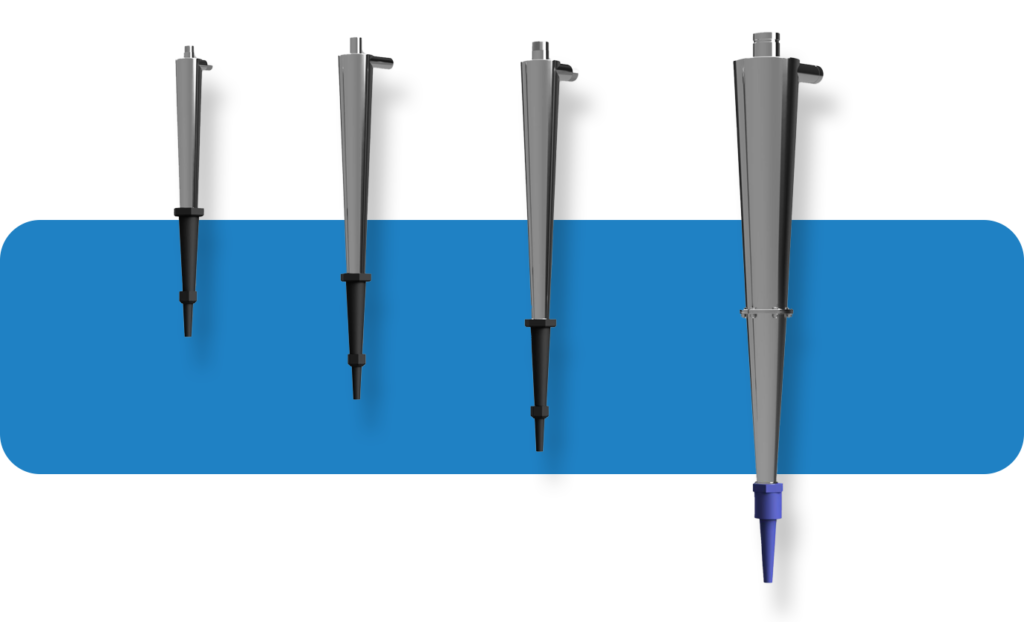

With upper cones made of acid-resistant steel and intermediate cones as well as reject nozzles made of plastic, we focus on the highest quality and durability.

Hydrozyklone als optimale Lösungen für Trennung, Klassierung & Reinigung von Flüssigkeiten, Suspensionen und Gemischen. Anwendungsbeispiele:

paper and pulp industry - Cleaning and processing of fiber dispersions in industrial plants through the use of special cleaning processes and state-of-the-art technologies.

Water treatment -Classifying and thickening end products and residues to obtain high-quality materials and efficient waste management.

Mechanical Engineering -Treatment of grinding water, recycling in battery cell production, waste water, recovery, environmental technology, water purification, desludging, water aeration.

Our products only use upper cones made of acid-resistant stainless steel. These are manufactured using a cold flow turning process, which achieves a high degree of rotational symmetry and internal smoothness. The lower areas can be individually adapted to the application scenario. Plastic is often used for this. This combines high wear resistance with good cost-effectiveness. Screw connections allow individual components to be changed quickly.

Consistently high selectivity: Consistently high precision of separation due to low surface roughness

Wear resistance: High material hardness enables long service life

Economy: Combination of different materials to reduce costs

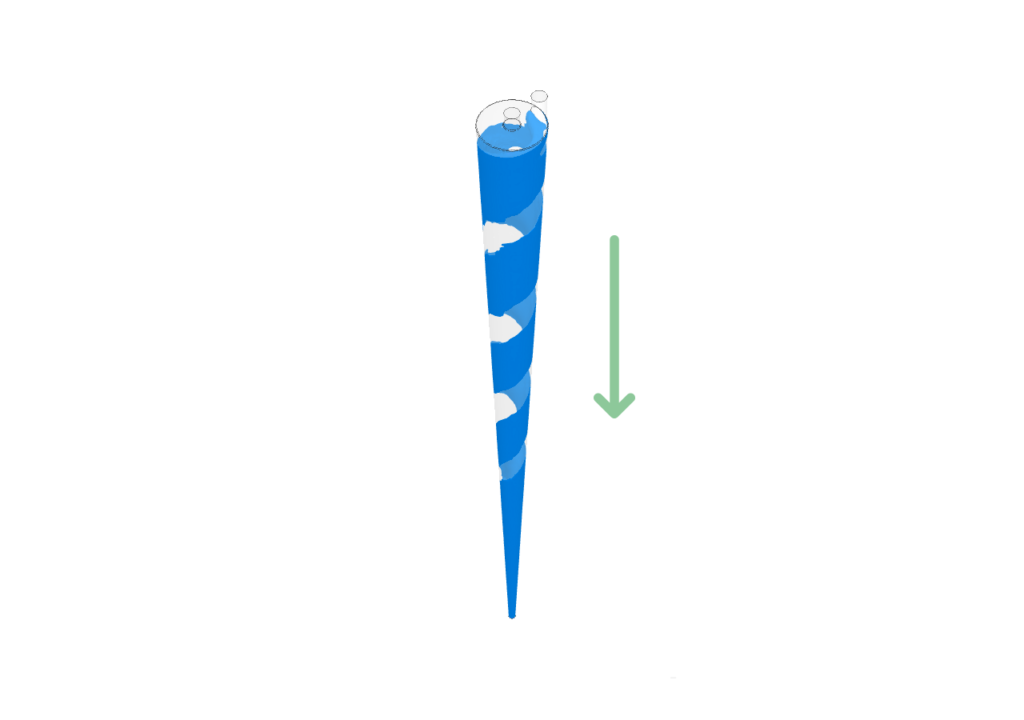

The Pan-Technik hydrocyclones have a low pitch, making them optimized for the separation of small particles such as sand. The design promotes the formation of a secondary vortex over a relatively wide differential pressure range, which improves the overall separation process.

Our products only use upper cones made of acid-resistant stainless steel. These are manufactured using a cold flow turning process, which achieves a high degree of rotational symmetry and internal smoothness. The lower areas can be individually adapted to the application scenario. Plastic is often used for this. This combines high wear resistance with good cost-effectiveness. Screw connections allow individual components to be changed quickly.

paper and pulp industry - Cleaning and processing of fiber dispersions in industrial plants through the use of special cleaning processes and state-of-the-art technologies.

Water treatment -Classifying and thickening end products and residues to obtain high-quality materials and efficient waste management.

Mechanical Engineering -Treatment of grinding water, recycling in battery cell production, waste water, recovery, environmental technology, water purification, desludging, water aeration.

Consistently high selectivity: Consistently high precision of separation due to low surface roughness

Wear resistance: High material hardness enables long service life

Economy: Combination of different materials to reduce costs

The Pan-Technik hydrocyclones have a low pitch, making them optimized for the separation of small particles such as sand. The design promotes the formation of a secondary vortex over a relatively wide differential pressure range, which improves the overall separation process.

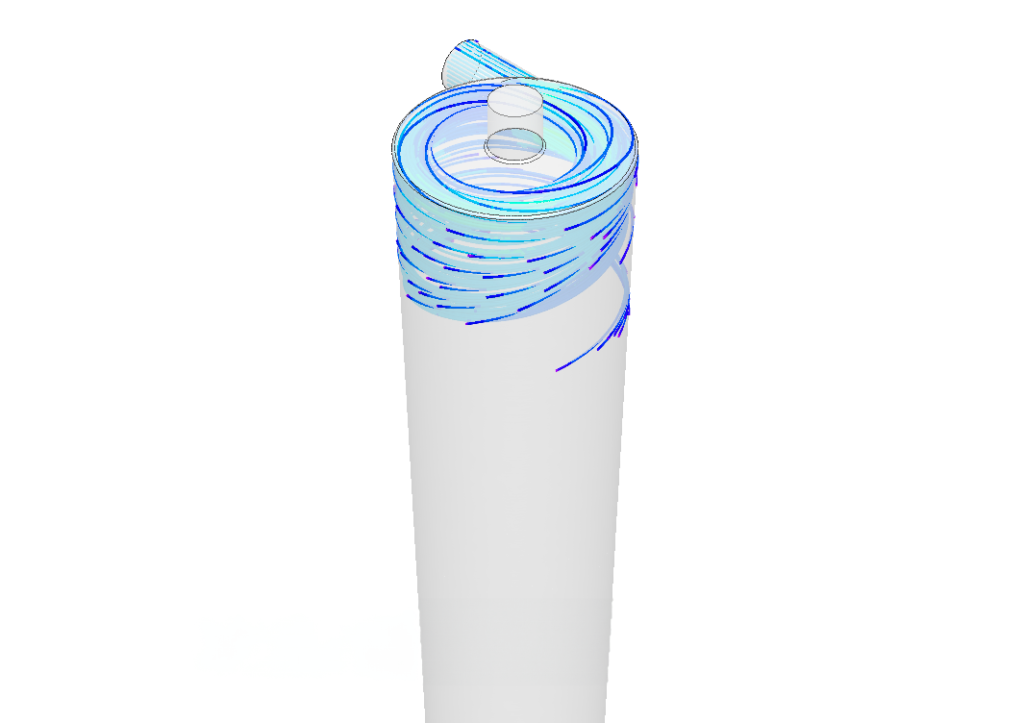

Rotatory movement in the hydrocyclone

The rotary flow in the hydrocyclone is created by the tangential supply of the suspension. This converts the kinetic energy of the suspension into a rotational movement. The suspension moves in a spiral shape towards the underflow nozzle.

Settling of heavy particles

The conical shape increases the rotation speed of the suspension. Heavier particles are pressed against the walls of the body by centripetal forces and moved to the underflow nozzle (apex). This throttling device ensures that only about 8-10% of the suspension escapes with the rejects.

Formation of the secondary vortex

The inhibition of the main flow at the underflow nozzle changes the direction of movement. A vacuum is formed in the center of the hydrocyclone, which creates a secondary vortex. This contains only light particles. The clarified liquid moves in a spiral against the primary vortex to the overflow (vortex).

The vacuum in the middle of the cyclone can be so strong that air is sucked in through the underflow nozzle (apex). This effect is used in aeration cyclones to specifically introduce air (or other gases) into liquids.

Our experts will be happy to assist you

Our experts will be happy to assist you

About us

About us

Welcome to Pan-Technik GmbH Munich.

Since 1995 our company has been developing innovative hydrocyclone technology and filter systems.

It is our goal to constantly increase the efficiency and reliability of our products. Through constant development and optimization, we continue to use the newest technology to always be able to offer you the best solutions.

We are convinced that every production process can be optimized. Therefore, we are continuously developing technologies that improve performance, sustainability and longevity of our products

About us

About usWelcome to Pan-Technik GmbH Munich.

Since 1995 our company has been developing innovative hydrocyclone technology and filter systems.

It is our goal to constantly increase the efficiency and reliability of our products. Through constant development and optimization, we continue to use the newest technology to always be able to offer you the best solutions.

We are convinced that every production process can be optimized. Therefore, we are continuously developing technologies that improve performance, sustainability and longevity of our products

Our company history - competence since 1995

Our company history - competence since 1995

Pan-Technik GmbH, founded in 1995 in Munich, has established itself through 30 years of experience an innovation as trusted partner for projects in the field of water treatment.

Initially specialising in recycling systems for washing water treatment in car washes, over the years the company has increasingly focused on hydrocyclone technology This specialization has enabled us to position ourselves as a leading provider for the efficient separation and cleaning of liquids and suspensions.

Today managed by the second generation Pan-Technik GmbH is a recognized expert in hydrocyclone technology. Our innovative solutions provide precise particle separation and classification, ideal for many industrial applications.

Trust in our many years of experience and our commitment to highest quality and customer satisfaction. Pan-Technik GmbH helps you to master your industrial challenges with tailor-made solutions. Lösungen successfully

Our company history - competence since 1995

Our company history - competence since 1995Pan-Technik GmbH, founded in 1995 in Munich, has established itself through 30 years of experience an innovation as trusted partner for projects in the field of water treatment.

Initially specialising in recycling systems for washing water treatment in car washes, over the years the company has increasingly focused on hydrocyclone technology This specialization has enabled us to position ourselves as a leading provider for the efficient separation and cleaning of liquids and suspensions.

Today managed by the second generation Pan-Technik GmbH is a recognized expert in hydrocyclone technology. Our innovative solutions provide precise particle separation and classification, ideal for many industrial applications.

Trust in our many years of experience and our commitment to highest quality and customer satisfaction. Pan-Technik GmbH helps you to master your industrial challenges with tailor-made solutions. Lösungen successfully

Contact us

Contact usOur experienced team will assist you in designing and adapting our hydrocyclones to your individual requirements. Send us your inquiry without obligation and we will contact you as soon as possible.

contact form

contact formUnser Team wird Ihnen in Kürze auf Ihre Fragen antworten.